All details [ liability-free ]

Please get further data from the data sheet:

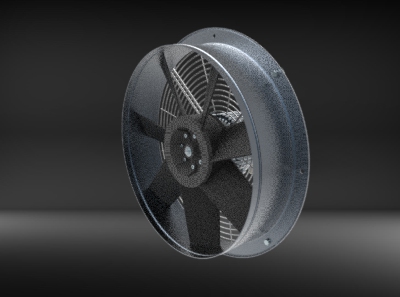

Axialfan LD352

The axial fan is also deliverable into high-grade steel and for the offshore use at a corresponding execution, see high-grade steel ventilators and offshore ventilators.

built-on ventilator

available from stock

built-in ventilator

available from stock

plate ventilator

available from 50 pieces

Description of the LD352 axial fan

The LD352 type axial fan runs efficiently and quietly at 1400 rpm with a flow rate of 5400 m³/h. The fan has a voltage of 400 volts and a diameter of 350 mm.

Due to the flexible design of the fans, the areas of application are versatile, so they are used for ventilation of or in machines, but also for ventilation of offices or smaller generator rooms.

Voltage and control of the LD352 axial fan

The AC fans can be controlled at 230 volts by temperature controllers (TR46).

When the fans are used in offices, air quality controllers are often used to control the fan to make the air in the offices even more comfortable. The fans are also so commonly used in stable buildings.

Fan voltage is 400 volts and 50 hertz, but voltages of 480 volts and 60 hertz are also supplied for the United States. For Canada, voltages of 575 volts and 60 hertz are available, and special voltages of 500 volts and 50 hertz are also available if needed.

Our range also includes transformer-type speed controllers, which provide easy control of fans throughout the speed range.

The speed controllers can also easily control the 230 volt AC fans steplessly and electronically. For this purpose, the control can be extended not only by air quality controllers, but also by CO2 controllers and temperature controllers.

Frequency converters can control the three-phase motors. However, depending on the frequency converter, it must be noted that an all-pole sinusoidal filter must be added between the motor and the fan (DIN-IEC/TS 60034-17).

Stainless steel versions of the LD352 axial fan

Stainless steel fans are also available. Fans in V2A (material number 1.4301 or AISI 304 or X5CrNi189) are often ordered for the food industry, while fans in special stainless steel V4A (material number 1.4571 or AISI 316 or X10CrNiMoTil810) are often ordered for locations with salty air.

For the food industry, the aluminum material from which the motors are cast as standard can be left raw or painted with food color. In the case of regular acceptance, a special aluminum material approved for the food industry is also conceivable for production upon request.

Special painting with salt water resistant paint is also possible for offshore applications.

Material of the LD352 axial fan

Impellers are made of high quality glass fiber reinforced plastic, but aluminum impellers can also be supplied for high temperatures.

The variant of rectangular plate fan is also available from a minimum order quantity and upon request.

Also the standard IP44 protection can be extended to IP54 or IP56.

When ordering, the air direction can be freely selected, thus the flow of air can also be flexibly decided.

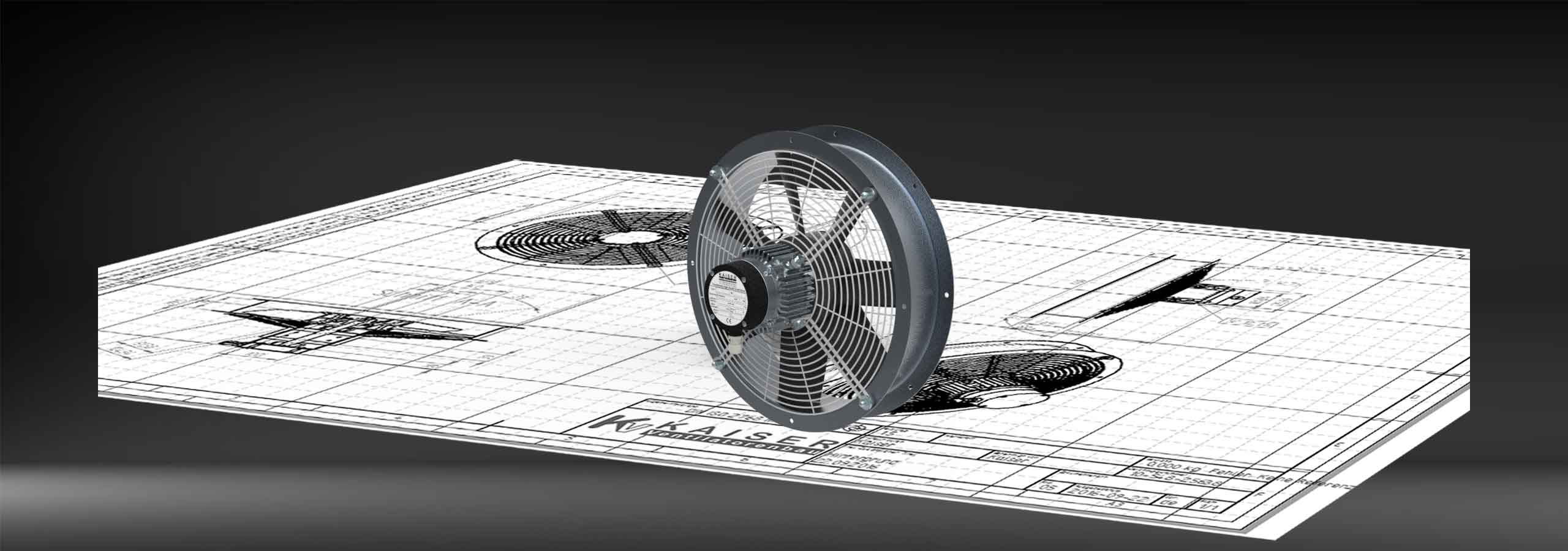

Technical diagram of the LD352 axial fan

Due to the flexible design, the air direction of the fans can always be reversed, even after the unit has been installed. Since the axial blades of the impellers are profiled for optimum efficiency with the standard air direction, an air performance loss of 15% must be expected with reversed air direction.

The motors, which are not standard motors but have been specially developed by Kaiser Ventilatorenbau and individually adapted to each axial fan, carry the high thermal protection class F or H according to DIN EN 60085.

Type tests for bearing and installation temperature, IPx6 tests for humidity class and salt water tests for the stainless steel fans in the offshore area are permanently available and can be requested if required.

The fan is energy efficient in its design and construction, complies with the ERP 2015 Ecodesign Directive (ErP Directive 2009/125/EC EU Regulation No. 327/2011) and thus carries the CE mark.

Weather protection dampers and discharge protection grilles are additionally available.

CAD data of the fan in STEP exchange format can be downloaded at any time and is available on our website. This makes it very easy to integrate the fans into the design, even without obligation and before ordering.

back to: axial fans